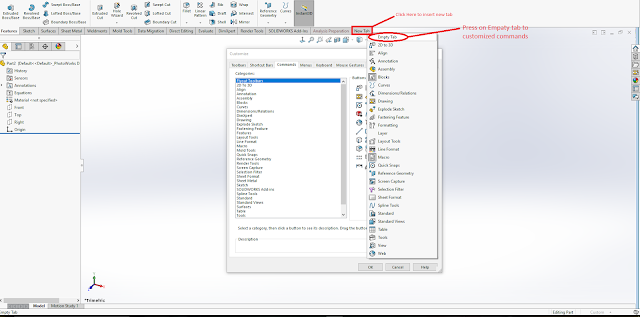

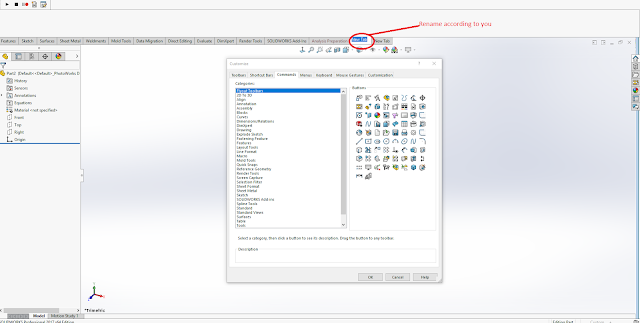

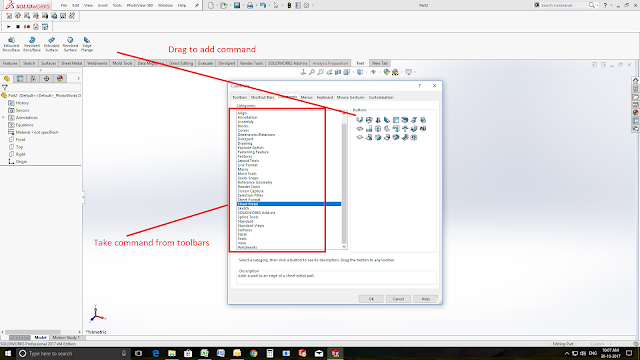

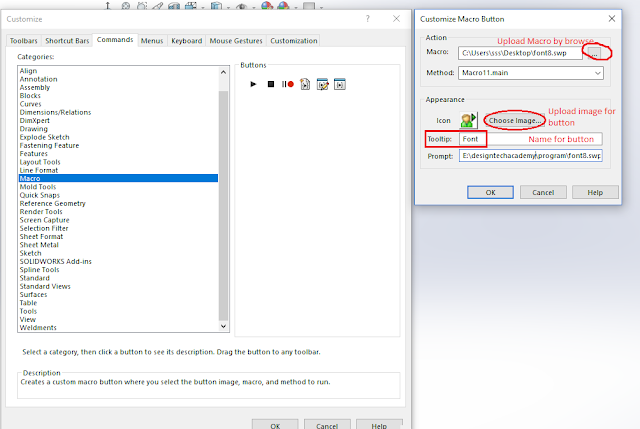

This program/code will help to manage the all font in same size with one click in solidWorks drawing. you can make a command tool in drawing by this macro.

This program will cover-

- Dimension font size

- Section view font size

- Diameter text location - horizontal

- Note font size

- Size of detail font size

- Save file after done all changes

In this program, font size is 8. you can change it as per requirement.

Dim swApp As Object

Dim Part As Object

Dim boolstatus As Boolean

Dim longstatus As Long, longwarnings As Long

Sub main()

Set swApp = Application.SldWorks

Set Part = swApp.ActiveDoc

'dimension font size

Dim myTextFormat As Object

Set myTextFormat = Part.Extension.GetUserPreferenceTextFormat(swUserPreferenceTextFormat_e.swDetailingDimensionTextFormat, swUserPreferenceOption_e.swDetailingDimension)

myTextFormat.CharHeightInPts = 8

boolstatus = Part.Extension.SetUserPreferenceTextFormat(swUserPreferenceTextFormat_e.swDetailingDimensionTextFormat, swUserPreferenceOption_e.swDetailingDimension, myTextFormat)

'section font size

Dim myTextFormat1 As Object

Set myTextFormat1 = Part.Extension.GetUserPreferenceTextFormat(swUserPreferenceTextFormat_e.swDetailingSectionTextFormat, 0)

myTextFormat1.CharHeightInPts = 8

boolstatus = Part.Extension.SetUserPreferenceTextFormat(swUserPreferenceTextFormat_e.swDetailingSectionTextFormat, 0, myTextFormat1)

Set myTextFormat1 = Part.Extension.GetUserPreferenceTextFormat(swUserPreferenceTextFormat_e.swDetailingSectionLabelNameTextFormat, 0)

myTextFormat1.CharHeightInPts = 8

boolstatus = Part.Extension.SetUserPreferenceTextFormat(swUserPreferenceTextFormat_e.swDetailingSectionLabelNameTextFormat, 0, myTextFormat)

Set myTextFormat1 = Part.Extension.GetUserPreferenceTextFormat(swUserPreferenceTextFormat_e.swDetailingSectionLabelLabelTextFormat, 0)

myTextFormat1.CharHeightInPts = 8

boolstatus = Part.Extension.SetUserPreferenceTextFormat(swUserPreferenceTextFormat_e.swDetailingSectionLabelLabelTextFormat, 0, myTextFormat)

Set myTextFormat1 = Part.Extension.GetUserPreferenceTextFormat(swUserPreferenceTextFormat_e.swDetailingSectionLabelScaleTextFormat, 0)

myTextFormat1.CharHeightInPts = 8

boolstatus = Part.Extension.SetUserPreferenceTextFormat(swUserPreferenceTextFormat_e.swDetailingSectionLabelScaleTextFormat, 0, myTextFormat)

Set myTextFormat1 = Part.Extension.GetUserPreferenceTextFormat(swUserPreferenceTextFormat_e.swDetailingSectionLabelDelimiterTextFormat, 0)

myTextFormat1.CharHeightInPts = 8

boolstatus = Part.Extension.SetUserPreferenceTextFormat(swUserPreferenceTextFormat_e.swDetailingSectionLabelDelimiterTextFormat, 0, myTextFormat)

Set myTextFormat1 = Part.Extension.GetUserPreferenceTextFormat(swUserPreferenceTextFormat_e.swDetailingSectionView_RotationTextFormat, 0)

myTextFormat1.CharHeightInPts = 8

boolstatus = Part.Extension.SetUserPreferenceTextFormat(swUserPreferenceTextFormat_e.swDetailingSectionView_RotationTextFormat, 0, myTextFormat)

'diameter text location

boolstatus = Part.Extension.SetUserPreferenceInteger(swUserPreferenceIntegerValue_e.swDetailingDimensionTextAndLeaderStyle, swUserPreferenceOption_e.swDetailingDiameterDimension, swDisplayDimensionLeaderText_e.swBrokenLeaderHorizontalText)

boolstatus = Part.Extension.SetUserPreferenceInteger(swUserPreferenceIntegerValue_e.swDetailingDimensionTextAndLeaderStyle, swUserPreferenceOption_e.swDetailingRadiusDimension, swDisplayDimensionLeaderText_e.swBrokenLeaderHorizontalText)

'note font size

Dim myTextFormat2 As Object

Set myTextFormat2 = Part.Extension.GetUserPreferenceTextFormat(swUserPreferenceTextFormat_e.swDetailingNoteTextFormat, 0)

myTextFormat2.CharHeightInPts = 8

boolstatus = Part.Extension.SetUserPreferenceTextFormat(swUserPreferenceTextFormat_e.swDetailingNoteTextFormat, 0, myTextFormat2)

'SIZE OF DETAILS

Dim myTextFormat3 As Object

Set myTextFormat3 = Part.Extension.GetUserPreferenceTextFormat(swUserPreferenceTextFormat_e.swDetailingDetailTextFormat, 0)

myTextFormat3.CharHeightInPts = 8

boolstatus = Part.Extension.SetUserPreferenceTextFormat(swUserPreferenceTextFormat_e.swDetailingDetailTextFormat, 0, myTextFormat)

Dim myTextFormat4 As Object

Set myTextFormat4 = Part.Extension.GetUserPreferenceTextFormat(swUserPreferenceTextFormat_e.swDetailingDetailView_NameTextFormat, 0)

myTextFormat4.CharHeightInPts = 8

boolstatus = Part.Extension.SetUserPreferenceTextFormat(swUserPreferenceTextFormat_e.swDetailingDetailView_NameTextFormat, 0, myTextFormat)

Set myTextFormat4 = Part.Extension.GetUserPreferenceTextFormat(swUserPreferenceTextFormat_e.swDetailingDetailView_LabelTextFormat, 0)

myTextFormat4.CharHeightInPts = 8

boolstatus = Part.Extension.SetUserPreferenceTextFormat(swUserPreferenceTextFormat_e.swDetailingDetailView_LabelTextFormat, 0, myTextFormat)

Set myTextFormat4 = Part.Extension.GetUserPreferenceTextFormat(swUserPreferenceTextFormat_e.swDetailingDetailView_ScaleTextFormat, 0)

myTextFormat4.CharHeightInPts = 8

boolstatus = Part.Extension.SetUserPreferenceTextFormat(swUserPreferenceTextFormat_e.swDetailingDetailView_ScaleTextFormat, 0, myTextFormat)

Set myTextFormat4 = Part.Extension.GetUserPreferenceTextFormat(swUserPreferenceTextFormat_e.swDetailingDetailView_DelimiterTextFormat, 0)

myTextFormat4.CharHeightInPts = 8

boolstatus = Part.Extension.SetUserPreferenceTextFormat(swUserPreferenceTextFormat_e.swDetailingDetailView_DelimiterTextFormat, 0, myTextFormat)

'save file

Dim swErrors As Long

Dim swWarnings As Long

boolstatus = Part.Save3(1, swErrors, swWarnings)

End Sub

Download Macro- Click Here