Reasons for Drafts:

1. Easier Mold Release:

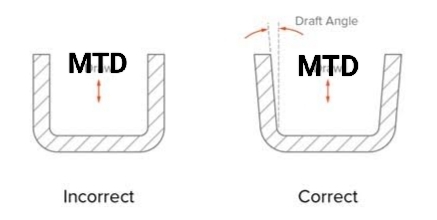

During injection molding, the plastic part cools and shrinks slightly, which can cause it to stick to the mold surfaces. A draft angle (a slight taper) allows the part to be released without damaging the part or the mold.

2. Prevents Part Damage:

Without a draft, the part may experience scratches, warping, or deformation during ejection from the mold.

3. Reduces Ejection Force:

A draft reduces the friction between the part and the mold, requiring less force to eject the part.

4. Improves Surface Finish:

Proper drafts ensure the part comes out smoothly, avoiding drag marks or defects on the surface.

5. Extends Mold Life:

By reducing the wear and tear during ejection, drafts help extend the mold's lifespan.

---

Why Minimum Draft Values?

1. Dimensional Accuracy:

Excessive draft angles can alter the intended dimensions of the part, especially in areas where precision is critical.

2. Aesthetic Requirements:

Overly large drafts might affect the design or appearance of the part, leading to customer dissatisfaction.

3. Functional Fit:

Parts with excessive drafts might not fit well with other components in assemblies.

4. Material Properties:

Some plastics shrink more than others. A minimum draft angle should consider the material's shrinkage rate to balance ease of ejection with the part's integrity.

---

Typical Minimum Draft Angles:

General rule: 0.5° to 2° is sufficient for most plastic parts.

Texture considerations: For textured surfaces, drafts of 3° or more may be required to prevent sticking.

By designing with the correct minimum draft angle, manufacturers can ensure efficient production, maintain quality, and reduce costs.

No comments:

Post a Comment